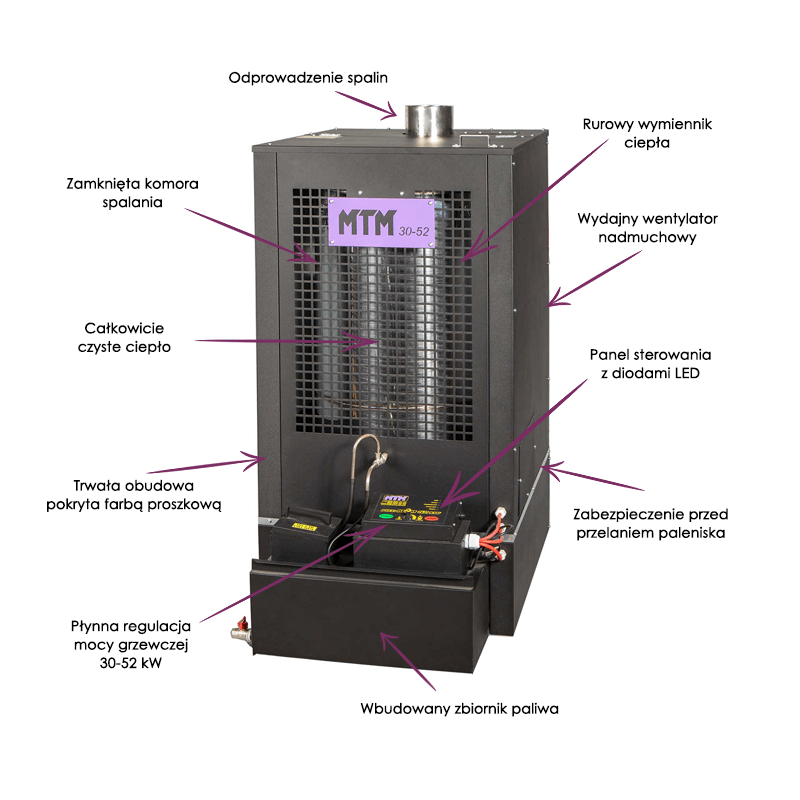

The MTM 30-52 ECO WARM multi-oil air heater is intended for heating industrial premises not covered by the central heating system.

Safe and secure shopping

Fast shipping

Satisfaction guaranteed

MTM 30-52 ECO WARM multi-oil blast furnace. The model is equipped with air outlets, enabling the connection of air ducts and transporting warm air to other rooms or over long distances, as well as setting the hot air outlets in a specific direction.

Power control consists in smoothly increasing or decreasing the revolutions of the fuel feeding pump. Burning takes place evenly, regardless of the thickness of the oil. A high-precision, low-speed gear fuel pump, specially designed for our devices, taking into account the specific conditions of use, pumps any type of oil, regardless of its density. Thanks to this, you do not have to check the density of the oil at your disposal and you do not have to remember to select the appropriate operating mode - the pump installed in our devices pumps both thick used oils and thinner heating oils and their mixtures.

The fuel filler is designed in such a way as to easily and quickly add fuel, without fear that we will flood the controller or larger contaminants will get into the tank. The easy-to-remove filter allows you to clean it quickly and efficiently.

New, improved system to prevent oil overflow in the combustion chamber, thanks to a more sensitive micro-switch.

Improved device electronics. Now you do not have to wonder what voltage you have in the network, because in our latest controller we have used a voltage stabilization system. Over-voltage protection increases the service life of the controller.

The MTM 30-52 ECO WARM heater has a closed combustion chamber with an additional oxygenating fan and the possibility of drawing air from another room or from outside. Thanks to this solution, the heater can work in rooms with slightly increased dustiness, e.g. paint preparation plants, and with extraction machines creating negative pressure.

The combustion chamber is made of stainless steel, while the fire bowl is made of cast iron, not of rapidly cooling steel.

The MTM 30-52 ECO WARM heater effectively heats rooms up to 1500m³ (with good insulation of the building).

The MTM 30-52 ECO WARM universal oil stove controller is equipped with a control knob and two buttons that allow the user to control the operation of the heater and LEDs indicating the operating status of the device combined with an acoustic signal in the event of a failure.

Smooth regulation of the heating power 30-52 kW

Heating power

30-52 kW

Oil consumption

from 3 to 5.2 l / h

Air flow

5500 m³ / h

Rated current

1.3 A

Electric supply

230 V / 50 Hz

Power consumption

300 W.

The diameter of the flue

150 mm

Dimensions W x D x height

1300x600x1200 mm

Weight

120 kg

Tank capacity

90 l

The MTM 30-52 ECO WARM multi-oil air heater is intended for heating industrial premises not covered by the central heating system.